* Engine components

Types of engine components:-

1. Engine head

2. engine block

3. Liners

4. crank-shaft

5. connecting rod

6. piston

7. piston ring

8. camshaft

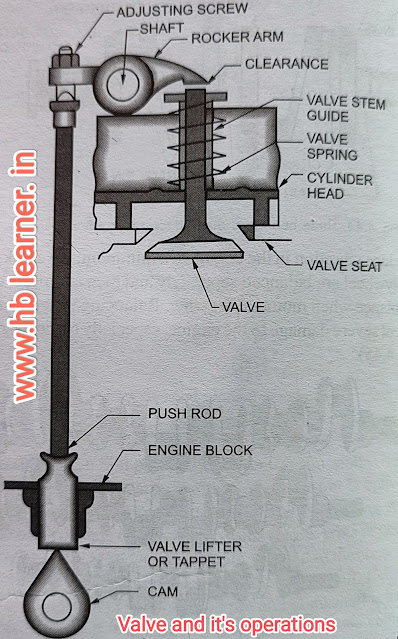

9. valve

10. valve and it's operation

11. intake manifold

12. exhaust manifold

13. spark plug

14. Fly wheel

15. carburetor

16. Radiator

17. Thermostate valve

18. Distributor

19. Ac mechanical pump

20. Lubricating oil pump

21. Air filter

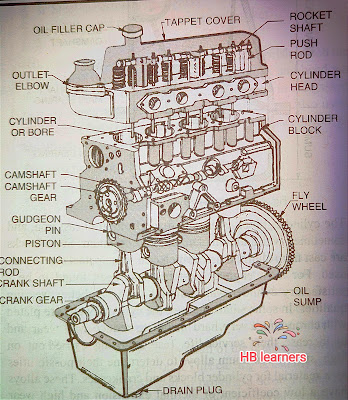

1.Engine Bolck:- The top of the cylinder is covered by a separate cast piece known as the cylinder head. The cylinder head is bolted to the top of the cylinder block. It contains combustion chamber. Spark plug and sometimes valves (in I-and F-head) are mounted in it. It incorporates passages for the flow of cooling water.The cylinder head is usually made of gray iron or aluminum alloy. Aluminum has the advantages of lightness in weight and high heat conductivity. It is cast separately from the cylinder block so that it may be removed for cleaning carbon and grinding valves. To retain compression in the cylinder, a flat piece of gasket is placed between the cylinder head and the cylinder block. In certain cases, such as a racing car engine, a separate head is not used. But a single piece of cylinder block and head is difficult and costlier to make; and the internal parts of the engine are not as accessible.

2.Engine block:- Cylinder block, cylinder head and crankcase-these three parts form the foundation and main stationary body of the automobile engine. They serve as support and enclosure for moving parts. In modern engines, the cylinder block and crankcase form a single casting, which gives a rigid structure. Ribs are cast in the crankcase to give it extra strength and to support the main and, in some cases, the cam shaft bearings. The cylinder block may also have a separate crankcase for the crankshaft, which is mainly confined to large engines, marine and stationary engines. A separate aluminum crankcase would result in saving the weight as well as enable cheaper and quicker replacement.

The cylinder block is usually made from gray cast iron, and sometimes, with addition of nickel and chromium. Some blocks are cast from aluminum, in which cast iron or steel sleeves are used. For most engines, cast iron has been found to be a satisfactory cylinder wall material, as it has better wearing qualities. In some small engines, the cylinder walls are plated with chromium, a very hard metal, to reduce wall wear and to increase their service life. Tests are being carried out on high silicon-aluminum alloys to determine their possibilities as a material for cylinder blocks and crankcases. These alloys have a low coefficient of thermal expansion and high wear resistance.

7.Piston Rings:- Piston rings are fitted into the grooves of the piston to maintain good seal between the piston and the cylinder wall. There are three functions of the piston rings as follows:

|

.png)

.png)

.png)

.png)

.png)

.png)

.png)